Vertical Axial Flow Pump

What is a vertical axial flow pump?

A vertical axial flow pump is a common type of pump consisting of a vertically oriented shaft and an impeller shaped like a propeller in a pipe. Vertical axial flow pumps usually move fluid axially (i.e., along the shaft axis) using an impeller. The impeller can be driven directly by a sealed motor in the pipe or by a drive shaft that enters the pump tube from the side. A vertical axial flow pump falls under the rotor dynamic pump because it relies on the fluid’s momentum and velocity to generate pressure. The vertical axial flow pump is designed to excellently transport a high volume of water at low discharge pressure. However, some models can be adjusted to perform efficiently at different conditions by changing the impeller. Vertical axial flow pumps are widely used in pumping water from many sources, including oceans, lakes, rivers, cooling ponds, tanks, etc. A vertical axial flow pump has a compact structure and also provides the highest pump capacity.

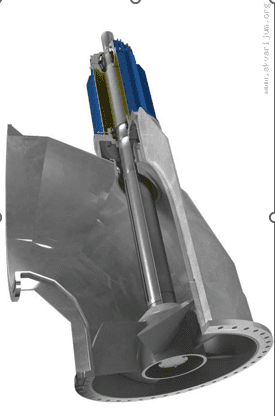

Figure: Showing a vertical axial flow pump

Components of a vertical axial flow pump

Prime mover

The prime mover is the source of the power for running the vertical axial flow pump. The prime mover can be an engine, a motor, a turbine, or a magnetic drive. Most vertical axial flow pump manufacturers use an electric motor as the prime mover because it is simple, low-cost, and easy to maintain compared to the other options. The electric motor’s operation can be based on either alternating current or direct current.

Pump casing

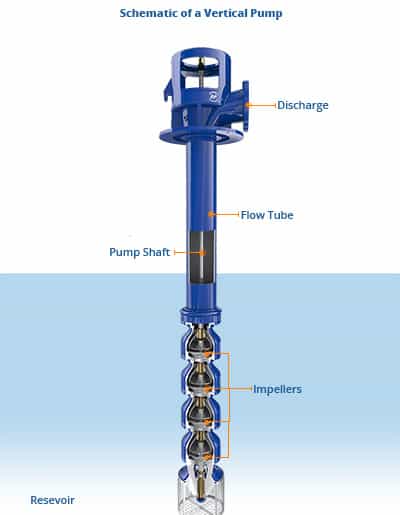

The casing is a narrow air- passage surrounding the impeller. The casing acts as a pressure containment vessel and also carries the suction and discharge ports. It contains the liquid and directs the flow into the pump through the suction pipe and out of the pump through the delivery pipe. The vertical axial flow pump manufacturers make pump casing using cast iron because it provides high tensile strength, durability, and abrasion resistance.

Shaft

The shaft is a cylindrical piece of metal lying along the center axis of the pump and supported on bearings. Its main functions are to carry the impeller and to connect the rotor with the prime mover through a flexible coupling. The pump shaft is usually manufactured using strong and durable materials such as stainless steel, alloy steel, carbon steel, etc. These materials are highly resistant to corrosion and strong enough to overcome vibrations.

Impeller

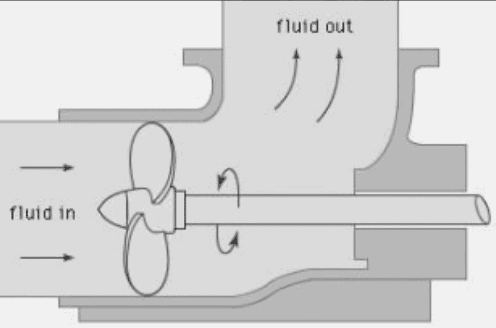

The impeller is the vertical axial flow pump’s rotating component. Its main function is to displace fluid through the pump by increasing the kinetic energy and pressure of the fluid. The impeller is usually mounted on the pump shaft and fitted in the pump casing with tight clearance. The vertical axial flow pump utilizes an axial flow impeller, which is designed with propeller blades to produce an axial flow with minimal shear and stress in the pumped fluid. The axial flow impeller helps to produce a fluid flow that moves parallel to the pump shaft. The axial impeller’s blades are fitted in a parallel arrangement, so they generate a very low pressure when pumping water. Vertical axial flow pump manufacturers can use a variety of materials for the impeller, including cast iron, stainless steel, bronze, etc.

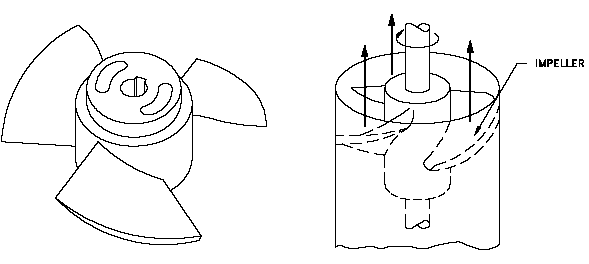

Figure: Showing an axial flow impeller and the direction of flow.

Bearings

The main purpose of the bearings is to support the rotor and to align it correctly with the fixed ends under the action of radial and axial forces. They also help to contain the relative motion of the rotor and to minimize the friction between the rotating shaft and the stator. The vertical axial flow pump utilizes anti-friction bearings (roller bearings), such as single-row ball bearings or double-row ball bearings.

Suction port

The suction pipe connects the pump with the inlet pipe to allow fluid into the pump. One end of the inlet pipe connects to the pump inlet and the other end dips into the water. The lower end of the inlet pipe is fitted with a foot valve to prevent the backward flow of water and a strainer to inhibit foreign bodies from entering the pipe.

Discharge port

The discharge port connects to the pump’s delivery pipe, helping to lift the pumped liquid to the required area or to deliver fluid to the piping network. Like the suction pipe, the delivery pipe also has two ends where one end connects to the pump outlet while the other end delivers the pimped liquid to a designed location e.g., a storage tank.

Figure: Components of a vertical axial flow pump

How does a vertical axial flow pump work?

When the motor is started, the pump’s shaft rotates the impeller at the same speed as the motor. As the axial impeller rotates, a vacuum is created inside the pump and the pumped fluid is pushed into the pump casing and towards the impeller due to the external atmospheric pressure. Once the fluid strikes the impeller blades, it is directed along a flow path parallel to the axis of the shaft at a very high velocity. As the fluid flows, the fluid particles do not change their radial position and the fluid, therefore, maintains a relatively straight direction from the suction pipe through the pump body to the discharge pipe. Since the impeller blades are arranged parallel to each other, the pump produces a high flow rate with a low-pressure head of about 35 feet.

Types of vertical axial flow pump

Magnetic drive vertical axial flow pump

A magnetic drive vertical axial flow pump uses the force of magnetism to move fluid through the pump. The magnetic drive technology, which generates the magnetism force, is made up of a driver magnet and a driven magnet. The driver magnet is located outside a hermetically sealed pump chamber, while the driven magnet is located inside the chamber. The hermetically sealed pump chamber makes the pump airtight, preventing fluid or vapor leakage. When the driver magnet rotates, it creates a magnetic field that interacts with the driven magnetic, creating a force that rotates the pump’s impeller to move the fluid axially through the pump body. The magnetic drive vertical axial flow pump presents a leak-proof design suitable for handling, hazardous, costly, and flammable liquid.

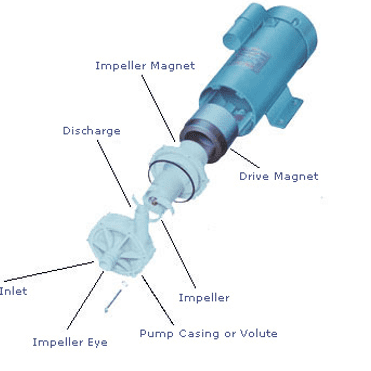

Figure: Showing a magnetic drive vertical axial flow pump.

Single-stage vertical axial flow pump

The single-stage vertical axial flow pump is made up of a single propeller-like impeller in the pump casing. This pump is comparatively simple in design and low cost compared to other types of vertical axial flow pumps. It is easy to install and occupies a small space.

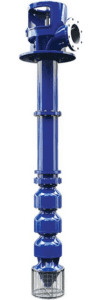

Figure: Showing a single-stage vertical axial flow pump.

Multistage vertical axial flow pump

A multistage vertical axial flow pump consists of two or more axial impellers mounted in series along the same vertical shaft. A vertical axial flow pump with multiple stages can achieve a significantly high-pressure head than the single-stage counterpart. The major disadvantage of this kind of pump is the increased sensitivity of the rotor to vibrations.

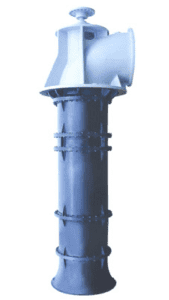

Figure: Showing a multistage vertical axial flow pump.

Between bearing vertical axial flow pump

In this type of vertical axial flow pump, the pump shaft is suspended at both ends between two bearings. As such the pump is supported on both ends. The between-bearing vertical axial flow pump can be either single stage or multi-stage pump. It can manage extremely high flow rates, significantly higher pressure, and heavier loading.

Submersible vertical axial flow pump

The Submersible vertical axial flow pump can operate below the surface of the pumped liquid. It is perfect for direct installation in discharge pipes, saving space and installation costs. Submersible vertical axial flow pump is widely used for land drainage, flood protection, and pumping stormwater.

Figure: Showing between bearing vertical axial flow pump.

Applications of a vertical axial flow pump

vertical axial flow pumps excellently cater to various industrial applications around the world, including urban and rural municipal water, power plants, agricultural irrigation, fisheries, wastewater treatment, and many more. Vertical axial flow pumps find the following uses:

- Vertical axial flow pumps are used extensively for pumping water from various sources, such as lakes, cooling ponds, tanks, rivers, oceans, and cofferdams.

- They are used in fermenters and power plants to circulate liquids.

- Vertical axial flow pumps are used for dewatering low-lying regions.

- They are also used in flood control, land drainage, and stormwater disposal.

- They are used in the chemical industry to circulate the liquid in the evaporator.

- They are also used for irrigation purposes in agricultural farms.

- Vertical axial flow pumps are also used for pollution effects control.

Advantages of a vertical axial flow pump

- Vertical axial flow pumps are excellent for low-head and high-flow applications.

- They are easily adjustable for best efficiency at varying conditions, such as high-flow/low-pressure and low-flow/ high-pressure.

- The effects of fluid rotation are less severe in vertical axial flow pumps.

- They can manage a relatively high flow rate than conventional centrifugal pumps.

- Vertical axial flow pumps have the smallest size among the many pump types in the market; a small size is easy to handle and use.

- The vertical axial flow pump’s power requirement decreases with the increasing flow rate of the pumped liquid.

Disadvantages of a vertical axial flow pump

- Vertical axial flow pumps produce low head and discharge pressures.

- They are not suitable for suction lifts.

- Vertical axial flow pumps are more expensive compared to conventional pump types.

- They cannot handle viscous liquids.

- They are unfit for applications requiring high heads.

Troubleshooting a vertical axial flow pump

The pump won start

- Blown fuse or tripped circuit breaker. Inspect the vertical axial flow pump for a blown fuse and replace it if necessary.

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

- Dirty or corroded fuse receptacles. Inspect and clean fuse receptacles if necessary.

The pump gives little or no discharge

- The pump is operating in reverse. Make sure the motor rotates in the direction indicated by the vertical axial flow pump manufacturer on the pump casing.

- The check valve has failed or is wrongly installed. Inspect the check valve, install it correctly or replace it.

- Clogged impeller. Inspect the impeller and clean any clogging material.

Pump operation is noisy

- The pump is working in cavitation. Ensure that the pump is working within the speed range specified by the vertical axial flow pump manufacturer.

- The pump bearings or impeller are severely won out. Inspect the bearing and impeller for wear and replace them if it is necessary.

The pump vibrates too much

- Some pump components of the vertical axial flow pump are unbalanced. Inspect and rebalance the components.

- Oblique or unbalanced shaft. Inspect the shaft and rebalance it as required.

- Loose pump assembly. Tighten pump components.

- The impeller is severely worn-out or defective. Inspect and replace the impeller.

Summary

A vertical axial flow pump is a common type of pump consisting of a vertically oriented shaft and a propeller-like impeller. The vertical axial flow pump usually moves the fluid in a flow path parallel to the shaft’s axis using a motor-driven axial impeller. The vertical axial flow pump classifies under the rotor dynamic pumps because it depends on the fluid’s momentum and velocity to generate pressure. The vertical axial flow pump manufacturers design the units to excellently cater to applications requiring high flow rates and low discharge pressure. Some models of vertical axial flow pumps can be adjusted to perform efficiently at different conditions by altering the impeller design. Vertical axial flow pumps are widely used in many industrial applications, including urban and rural municipal water, power plants, agricultural irrigation, and fisheries. They are available in different types and also present the smallest pump size in the market.