Non-clog Submersible Wastewater Pump

What is a non-clog submersible wastewater pump?

A non-clog submersible wastewater pump is a pump with a completely recessed impeller designed to operate below the surface of the wastewater. Its specially designed open impeller allows the passage of solid objects of sizes equal to the width of the pump’s discharge. The ability of the impeller to handle solids also provides outstanding clogging resistance and unbeaten pumping efficiency. A non-clog submersible wastewater pump designed as a single sealed unit combining a pump and integrated motor ideal for a wide range of operating speeds. Non-clog submersible wastewater pumps are usually made of cast iron and an external coating system providing corrosion resistance. The pump is used to transport wastewater by directing the flow to a treatment facility. Non-clog submersible wastewater pumps are commonly found in applications involving wastewater processing, sewage, affluent, and transferring solid laden media. They are suitable for permanent installations for discharging wastewater from washing machines, sinks, and showers, or drainage from the garden in private homes.

Figure: showing a non-clog submersible wastewater pump

Components of a non-clog submersible wastewater pump

Pump casing

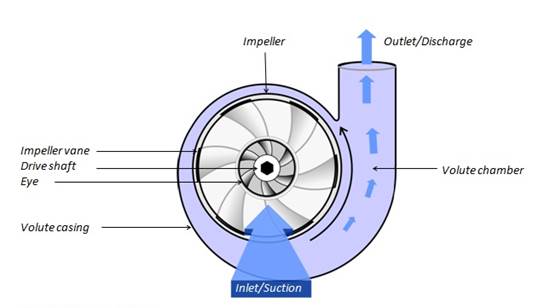

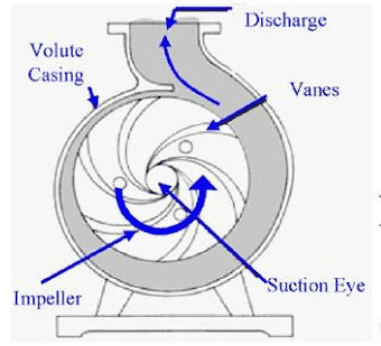

The pump casing contains the pump rotor and features the intake and discharge sections. It is usually manufactured from cast iron and insulated to protect the electrical and working parts of the pump. The pump casing can be either a volute or diffuser casing type. The volute casing consists of a spiral design and an offset impeller, creating a fluid passage that increases gradually towards the pump output. A diffusing casing is circular and contains several guide blades, surrounding the impeller in the pump assembly. Non-clog submersible wastewater pumps mostly use the volute casing design because excellently handles liquids with entrained solids and highly viscous ones. However, it is also common to find the diffuser casing in some non-clog submersible wastewater pumps because they are can be easily tailored for specific applications and are efficient.

Figure: showing volute casing design

Power cable

The power cable delivers electrical power to the non-clog submersible wastewater pump. The cable is made up of a range of conductors that help to meet the motor requirement.

Motor

The motor is the source of the mechanical power to run the pump. The motor is usually hermetically sealed to keep water from entering the motor. The non-clog submersible wastewater pump uses an AC induction motor, suitable for operating at a wide range of currents and voltages. The motor is also oil-filled to provide a pump tough enough to meet almost any application involving transporting fluid with slid materials.

Impeller

The impeller is the part of the pump rotating at high speed and acting to increase the fluid’s flow rate and pressure. Non-cog submersible wastewater pump manufacturers use close-grained cast iron or cast steel to manufacture the pump’s impeller.

Shaft

The purpose of the shaft is to transfer mechanical torques from the motor to the impeller during pump operation. The non-clog submersible pump manufacturers prefer corrosion-resistant stainless steel and carbon steel for manufacturing pump shafts. These materials are chosen because they are less corrosive, and can overcome heavy loads and vibrations during the pump operation.

Bearings

The bearings carry the shaft and the impeller and ensure they align correctly with the fixed ends under the action of radial and axial forces. Bearings also serve to reduce the friction between the rotating shaft and the stator and contain the relative motion of the rotor assembly.

Intake section

The intake section is also called the suction manifold. Its function is to allow the pumping fluid into the pump and toward the impeller’s eye.

Check and bleeder valves

The check valves help to maintain a full column of water above the pump. Without it, fluid from the pipes would flow back through the pump when the motor stops. The bleeder serves to prevent pulling wet tubing.

How does a non-clog submersible wastewater pump work?

When the pump is started, the pump impeller rotates and displaces the liquid inside the pump, creating a vacuum in the impeller’s eye. Due to this vacuum, more and more liquid draws into the pump casing as the pump runs. So long as the impeller rotates, the liquid will be continuously sucked in to be transferred. In the pump casing, the liquid rotates with the impeller while the centrifugal force acting on the impeller pushes it from the center of the impeller to the outer edges at a very high velocity. The fluid finally enters the volute casing where it builds a very high static pressure as the fluid flow decreases due to the gradually expanding flow path. The fluid is then discharged to the delivery pipe at a very high pressure which allows it to be pushed to the surface and to flow to the required location through the piping network.

Types of non-clog submersible wastewater pumps

Single suction non-clog submersible wastewater pump

In this pump type the pumped liquid from one side of the pump impeller and exits from the other side. This pump has a compact construction and smooth operation

Double suction non-clog submersible wastewater pump

In a double suction non-clog submersible wastewater pump, the fluid enters from either side of the pump impeller and then converges at the middle of the impeller where it discharges through the delivery pipe. The double suction can manage higher flows than the single suction. It is also free of cavitation because it reduces the inlet flow.

AP 50 non-clog submersible wastewater pump

This pump type can pump non-aggressive wastewater with slid particles of sizes up to 50 mm.

AP 70 and 80 non-clog submersible wastewater pump

The Ap 70 and model can accommodate particles with maximum sizes of 70 and 80 mm respectively.

Applications of non-clog submersible wastewater pumps

A non-clog submersible wastewater pump is excellent for many industrial applications including, wastewater treatment plants, mining, dredging, drainage in homes, industrial and domestic wastewater, etc. non-clog submersible wastewater pumps find the following uses:

- They are used for pumping industrial and domestic wastewater treatment

- They are used in wastewater treatment plants

- They are used for draining sinks, and washing machines, and for garden draining in private homes.

- They are used for transporting liquids with a high percentage of solid contents.

- They are also used for greywater or effluents in various manufacturing industries

- They are used for transporting liquid with suspended solids and corrosive and abrasive liquids.

- They are also used in construction, dewatering, and flood control.

Advantages of a non-clog submersible wastewater pump

- A non-clog submersible wastewater pump offers the ability to handle solids without clogging. The open and recessed rotor design enables the pump to pass fluid laden with very large solid particles such as rocks without damaging or clogging the pump.

- The pump’s material is highly corrosion resistant making the pump a perfect option for pumping abrasive and corrosive materials.

- The pump does not experience cavitation during operating.

- A non-clog submersible wastewater pump is highly efficient and energy saving.

- The pump is self-priming since it is submerged in water.

- Since the pump is submersible, it uses direct pressure to release fluid. A non-clog submersible wastewater pump, therefore, is more effective than non-submersible pumps.

- The pump design is convenient and easy to use.

- The advanced design provides trouble-free service and low-cost operation.

- The pump has a long service life because of the adequate design of the bearing and mechanical seals.

Disadvantages of a non-clog submersible wastewater pump

- A non-clog submersible wastewater pump might experience unnoticeable wear and tear of seals, which can cause pump leakage. Pump leakage can severely corrode the motor leading to motor failure.

- A non-clog submersible wastewater pump can overheat if not fully submerged in water during operation.

- The non-clog submersible wastewater pump’s design is more technical and the pump is a bit expensive to acquire

Troubleshooting a non-clog submersible wastewater pump

The motor fails to start

- The circuit breaker is tripped or the fuse is blown-out. Check and reset the circuit breaker if necessary. Inspect the pump for a blown fuse and replace it.

- There is no power supply to the non-clog submersible wastewater pump. Use a voltameter across the pump’s power lines to confirm if there is the power supply

- Shortcomings in pump wiring. Inspect the pump for loose connections or broken wires and fix them. Check that pump’s wiring is correct according to the non-clog submersible wastewater pump manufacturer’s wiring diagram.

- The pump lacks overload protection. Check that the circuit breaker and fuses are operating correctly; replace them if necessary.

Zero pump discharge

- The non-clog submersible wastewater pump is air locked. Trying starting and stopping the non-clog submersible wastewater pump repeatedly until it delivers fluid.

- The water level is too low in non-clog submersible wastewater pumps. limit the pump output flow rate for the pump to fill up and re-start.

- The pump is operating in reverse. Reverse the motor polarities. Check that the motor rotation direction follows the submersible sludge slurry pump manufacturer’s guide.

- The discharge pipe is blocked. Inspect and clean the discharge pipe.

- The impeller is clogged. Clean the impeller to remove any blockage.

- The discharge line check valve is installed backward. Make sure the arrow on the check valve points in the direction of the arrow mark provided by the non-clog submersible wastewater pump manufacturer.

The Pump’s discharge is unstable

- Either the impeller or seal ring is severely worn out. Inspect and replace worn-out impeller or seal ring.

- There is a leakage in the bottom valve. Inspect the non-clog submersible wastewater pump’s bottom valve for any leakage and correct it.

- The voltage supply is too low, leading to a decrease in pump speed. Check that the supply voltage is sufficient for the pump. If not, adjust accordingly.

- There is leakage in the drop pipe. Lift the drop pipe to inspect and repair any leaks.

- There is a partial blockage in the pump intake screen. Clean the non-clog submersible wastewater pump’s intake screen from mud and sand blockage.

The pump’s capacity is low

- The pump is reversed. Reverse the non-clog submersible wastewater pump polarities

- The pump’s discharge pipe or piping network is blocked. Inspect and clear any blockage from the discharge pipes or piping network.

- The pump casing or impeller is partially clogged. Inspect and clean the pump interiors.

The pump is vibrating and noisy

- There is a large misalignment between the non-clog submersible wastewater pump’s shaft and the engine shaft. Inspect and realign the shafts.

- The pump bearings or impeller are severely won out. Inspect the bearing and impeller for wear and replace them if it is necessary.

- Some of the non-clog submersible wastewater pump components are unbalanced or loosely mounted. Inspect and rebalance the components. Tighten any loose component to the recommended torque level by the non-clog submersible pump manufacturer.

Summary

A non-clog submersible wastewater pump contains a completely recessed impeller and is designed to operate below the surface of the wastewater. The specially designed open impeller facilitates the passage of solid particles of sizes equal to the width of the pump’s discharge. The pump has high clogging resistance and pumping efficiency. A non-clog submersible wastewater pump combines a pump and integrated motor in a single sealed unit. The motor is usually oil-filled to create a pump tough enough for nearly all applications involving transporting fluid with solid materials. Non-clog submersible wastewater pump parts are mainly made from cast iron or stainless steel. They also have an external coating system, which further enhances corrosion resistance.

Non-clog submersible wastewater pumps are commonly found in applications involving wastewater processing, sewage, affluent, and transferring solid-laden media. Typical uses include pumping industrial and domestic wastewater, and transporting corrosive and abrasive liquids. Non-clog submersible wastewater pumps provide many benefits, including corrosion resistance, self-priming, cavitation-free operation, and many more.