API610 Vs1 and Vs5 Vertical Pump

What is API 610 Vs1 and Vs5 vertical pumps?

The API 610 Vs1 and Vs5 vertical pumps are a category of pumps manufactured according to the API 610 standards and are vertically suspended (Vs). API610 Vs1 and Vs5 vertical pump manufacturer’s design this pump with a single casing design comprising the impeller chamber and the diffuser/volute as a single part and not enclosed in a pressure case or can. The pump’s casings and impellers are submerged in the medium to be pumped, suspended vertically on a column below a support plate. The support plate is usually installed at the top of a tank and carries the motor and thrust bearings. Therefore, API 610 Vs1 and Vs5 vertical pumps are vertically suspended pumps with wet pit diffusers, single casing complying with the API 610 design standards.

The main difference between the API 610 Vs1 and Vs5 vertical pumps is that Vs1 discharges the pump fluid through the same upright column that suspends the bowl assembly. In contrast, a vs5 removes the pumping fluid through a separate column from the shaft column. The API Vs5 comprises a different line shaft cantilevered and supported by bearings in the top housing only and does not contain support bearings within the column. API610 Vs1 and Vs5 vertical pump manufacturers design the pump for great performance qualities such as a high flow rate of around 400 cubic meters per hour, a maximum discharge head of 200m, and a wide operating temperature range of -20 and 120 degree centigrade. Typical uses of API 610 Vs1 and Vs5 vertical pumps include wastewater treatment plants, the paper industry, steel-making and steel rolling plants, power generation plants, and chemical and petrochemical among others.

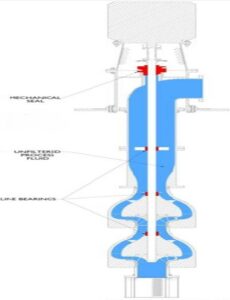

Figure: Showing the API 610 Vs1 vertical pump configuration

Design features of API 610 Vs1 and Vs5 vertical pumps

- Complies with API 610 requirements.

- Comprises the first-stage impeller with a low NPSH design.

- It has a side interface nozzle.

- Journal bearing distances as per the standards.

- Oil-lubricated antifriction bearings.

- Cantilever design without submerged bearings and shaft seal.

- The bearing assembly is sealed-off to prevent bearing contamination.

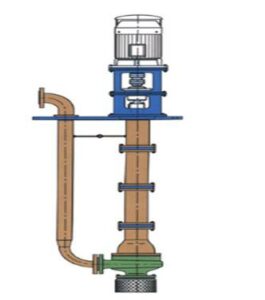

Figure: showing the API 610 Vs5 vertical pump configuration

Components of API 610 Vs1 and Vs5 vertical pump

Motor

The electric motor is the prime mover in API 610 Vs1 and Vs5 vertical pump, providing all the power required to run the pump. The electric motor is an electromechanical device that converts electrical energy from the mains electricity supply into mechanical energy. An electric motor can be either an AC motor or a DC motor. Ac motors work with alternating current, while Dc motors operate with direct current. The motor shaft usually couples with the pump shaft to transit toque.

Pump Shaft

The pump shaft is a rotary mechanical component riding on bearings and carrying the impeller. Its function is to rotate the impeller to displace the fluid in the pump. The pump shaft, bearing, and impeller form the rotor assembly, which connects to the electric motor through a coupling. API 610 Vs1 and Vs5 vertical pump manufacturers design the shaft using strong solid metals such as stainless steel and carbon steel.

Bearings

The bearings provide the end support to the shaft or the rotor and help align them correctly with the fixed ends under the action of radial and axial forces. They also help to contain the rotor’s relative motion and minimize the friction between the rotating shaft and the stator for smooth operation.

Impeller

The impeller is a rotor that serves the role of increasing the kinetic energy and pressure of the fluid. It is fitted with a series of backward-curved vanes. It is usually mounted on the pump shaft and housed in a watertight casing. As the impeller rotates, it transfers the kinetic energy derived from a source, i.e., an electric motor, to the fluid, thereby increasing the fluid pressure and inducing fluid flow. The impeller design is a significant factor in determining the pump’s efficiency. Impellers have two types: Axial flow impeller and Radial flow impeller. The fluid flows axially to the pump shaft in axial impellers, while in a radial impeller, the fluid moves perpendicularly to the post. Axial impellers primarily apply for high-flow and low-pressure applications. On the other hand, radial impellers find use in multistage split-case centrifugal pumps.

Impellers can also be classified as open impellers and closed impellers. Open impellers have only one shroud, and the vanes are exposed on one side and are mainly found in single-stage suction centrifugal pumps. A Closed impeller has a cover on either side of the vanes during a closed impeller. The impellers in API 610 Vs1 and Vs5 vertical pumps are vertically oriented, suspended below the support, and submerged into the medium.

Pump casing

The pump casing is the shell or housing protecting or supporting most of the pump components. It served to seal the pump, protect against leakage and retain pressure. It houses vital parts of the pump, such as the shaft, bearing, impellers, etc. The pump casing also contains the liquid and directs the flow through the suction pipe and out of the pump through the delivery pipe.

How does an API 610 Vs1 and Vs5 vertical pump work?

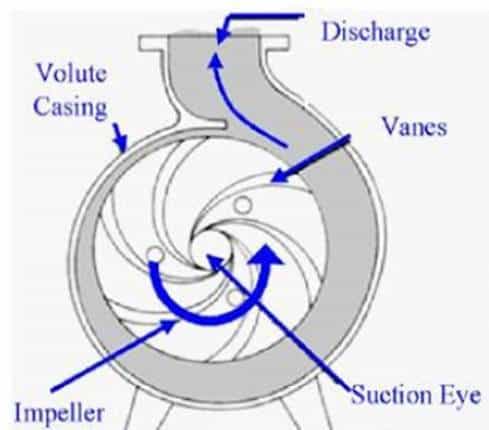

When the electric motor is powered, it converts the electrical energy into mechanical energy to turn the pump impeller with blades. As the impeller begins to turn, it imparts kinetic energy to the pumping medium. The centrifugal force through the impeller rotor causes the liquid to move radially outward at high tangential velocity, away from the impeller center of rotation. The swirling flow at the exit of the impeller is then directed into the diffuser where the fluid flow speed is gradually decreased leading to the conversion of the high-velocity energy into a high-pressure head. In vertically suspended pumps, the high exit pressure allows the fluid to be pumped to high vertical locations. Therefore, API 610 Vs1 and Vs5 vertical pump uses the high exit pressure force to lift the liquid to the desired locations, often at elevated residual pressure.

Figure: Working of API610 Vs1 and Vs5 vertical pump

Types of API 610 Vs1 and Vs5 vertical pump

The API 610 Vs1 and Vs5 vertical pumps can be single or multistage. The single-stage types have only one impeller and a diffuser installed within a single volute casing. In contrast, multistage types comprise three or more impellers and diffusers installed within the volute casing. The API 610 Vs1 and Vs5 vertical multistage pumps can achieve a lower Net Positive Suction Head (NPSH) by designing for it, specifically in the first stage, and then following it up with unique high head per stage series hydraulics in subsequent stages.

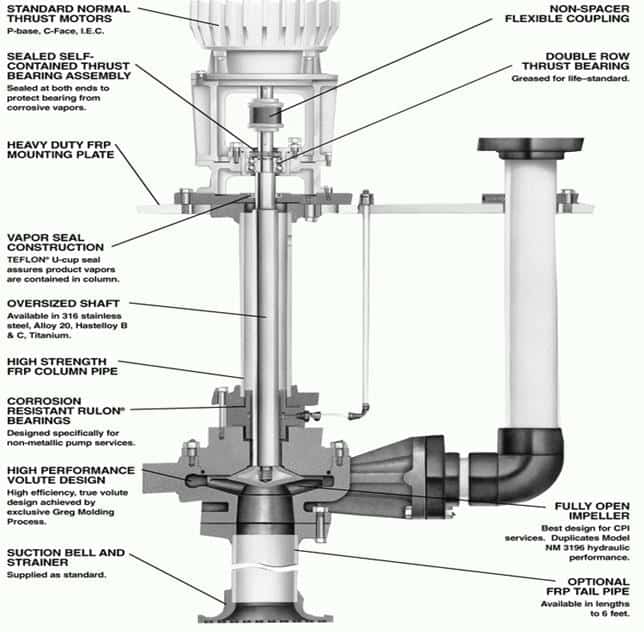

Figure: Showing API 610 VS1vertical multistage pump.

Figure: Showing API 610 VS5 vertical multistage pump.

Applications of API 610 Vs1 and Vs5 vertical pump

- They are used in minerals and mining processing applications.

- They are used in crude oil and oil product transportation.

- API 610 Vs1 and vs5 vertical pumps are used for industrial water supply.

- They are used for pumping abrasive liquids and liquids containing large solids.

- API 610 Vs1 and vs5 vertical pumps also apply in auxiliary services in power plants.

- They are also used for the transfer of fibrous and non-fibrous slurries containing large solids.

- They are used for the transfer of effluents and hazardous liquids.

- They are also used for pumping irrigation water.

- They are used to support industrial fire protection equipment.

- They are used in chemical processing plants

- They are used in food processing.

- API 610 Vs1 and Vs5 vertical pumps are used in underground storm water and drain water applications.

- They are used in condensate services.

- They are used in the transportation of liquefied petroleum gas.

Advantages of API 610 Vs1 and Vs5 vertical pump

- API 610 Vs1 and Vs5 vertical pumps are perfect for use when there is insufficient NPSHA for a horizontal pump.

- They are suitable for pumping all kinds of clean and contaminated liquids and slurry.

- They are adaptable and perfectly suited to all industrial sump pump applications.

- They are available in abrasion-resistant and corrosion-resistant materials, which resist wearing in challenging pumping applications.

- They are easy to assemble and maintain.

- They have high performance and durability.

- They have high reliability and operation efficiency.

The disadvantage of API 610 Vs1 and Vs5 vertical pump

- API 610 Vs1 and Vs5 vertical pump requires vertical clearance for installation and maintenance.

- Their weights accumulate below the volute which can lead to stress concentration.

- In API 610 Vs1, the fluid transfers from the sump through the support column and out into a discharge bend. However, the sharp turn on the discharge produces a loss in performance.

- The VS1 pump generally requires a double mechanical seal and plan seal support system to prevent leakage.

Troubleshooting API 610 Vs1 and Vs5 vertical pump

The pump won’t start

- Blown fuse or tripped circuit breaker. Inspect and replace the fuse as necessary

- Dirty or corroded fuse receptacles. Check and clean fuse receptacles as necessary

- The voltage is irregular due to dirt or corrosion at the pressure switch. Inspect the pressure switch and clean it of any debris or pollution.

Not enough water is running through the pump system

- The check valve has failed or is wrongly installed. Inspect the check valve, install it correctly or replace it

- The pump isn’t fully submerged. Make sure that the pump is fully immersed in the medium.

- The pump is air bound. Ensure that the pump system is free of air.

- Clogged impeller. Inspect the impeller and remove any material causing blockage.

- The pump is operating in reverse. Check that the direction of the motor rotation matches the direction indicated by the API610 Vs1 and Vs5 vertical pump manufacturer on the pump casing. Reverse the motor polarities.

Pump operation is noisy

- Pump working in cavitation. Ensure that the net suction pressure head isn’t too low and is per the API610 Vs1 and Vs5 vertical pump manufacturer’s specifications. Ensure that the suction line valves are fully open. Also, check that the fluid viscosity meets the pump manufacturer’s specifications.

- There is air in the fluid. Ensure the pump is fully submerged to prevent vortex formation on the fluid’s surface.

- The pump is working outside the design duty range. Ensure the pump is working within the duty range recommended by the manufacturer.

Pump experiencing excessive vibration

- Some pump parts are unbalanced. Inspect and rebalance components if it is necessary.

- The impeller is severely worn out or defective. Inspect and replace the impeller with another one from the API610 Vs1 and Vs5 vertical pump manufacturer if necessary.

- Oblique or unbalanced shaft. Inspect the post and replace or balance it as required.

The overload protector keeps tripping

- The protector is in direct sunlight. Shade or ventilate the box

- Incorrect voltage. Inspect the line terminals to determine if the pump is getting the voltage designed by the pump manufacturer.

Summary

The API 610 Vs1 and Vs5 vertical pumps can be described as vertically suspended, wet pit, diffuser pumps with a single casing and complying with the API 610 design standards. Their pump casings and impellers are submerged in the medium to be pumped, suspended vertically on a column below a support plate. The support plate is usually installed at the top of a tank and carries the motor and thrust bearings. The main difference between the API 610 Vs1 and Vs5 vertical pumps is that Vs1 discharges the pump fluid through the same upright column that suspends the bowl assembly. In contrast, vs5 discharges the pumping fluid through a separate column from the shaft column.

API610 Vs1 and Vs5 vertical pump manufacturers design these pumps for use in applications such as wastewater treatment plants, the paper industry, steel-making and steel rolling plants, power generation plants, and chemical and petrochemical. Advantages of this pump are simple and compact design, easy to repair, ability to handle slurries, resistant to corrosion, high volume flow rate, high pressure head, low thermal expansion, highly reliable, and durable.