Horizontal Centrifugal Pump

What is a horizontal centrifugal pump?

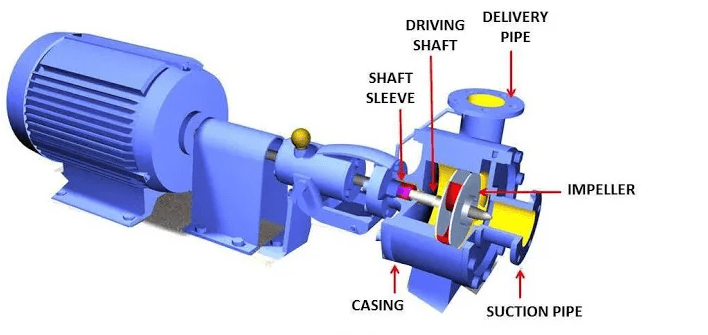

As the name suggests, a horizontal centrifugal pump is a pump that works while it is laid in the horizontal plane as shown in the figure below. A horizontal centrifugal pump has its shaft coupled with the motor or engine and impeller laid in the horizontal plane. A horizontal centrifugal pump could be either a single-stage (single impeller) or multistage (more than one impeller) pump. The horizontal alignment of this pump makes it easier to access pump internal parts for repair and maintenance.

Figure: Horizontal centrifugal pump

How do horizontal centrifugal pump work?

A horizontal centrifugal pump works by developing the velocity and pressure of the fluid being pumped. The pressure and velocity are responsible for moving the fluid from low levels to the required high levels. For a horizontal centrifugal pump to work, it uses its impeller and casing. These two parts are used to convert the energy-enhancing flow of the fluid. The impeller works by rotating at high speed while the casing remains stationary. The fluid enters the pump into the pump casing and then falls on the blades of the impeller. The impeller blades are whirled radially and tangentially outwards. The fluid then exits the impeller and goes to the diffuser which is part of the casing. The impeller is responsible for creating kinetic energy and pressure to the fluid. For multistage horizontal centrifugal pumps, more than one impeller is used thus producing more energy and pressure making the pump more powerful to transport fluid for a higher head.

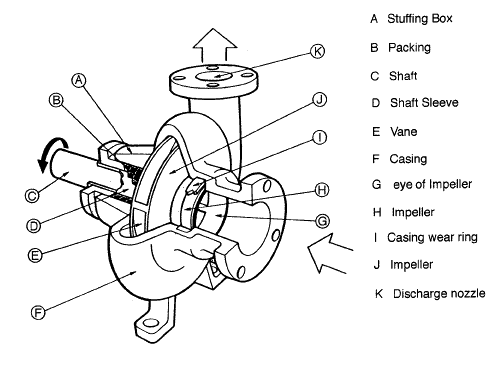

Main parts of a horizontal centrifugal pump

Figure: Main parts of a horizontal centrifugal pump

Impeller

An impeller in a horizontal centrifugal pump is a rotor that is used to increase the kinetic energy of the fluid flow.

Casing

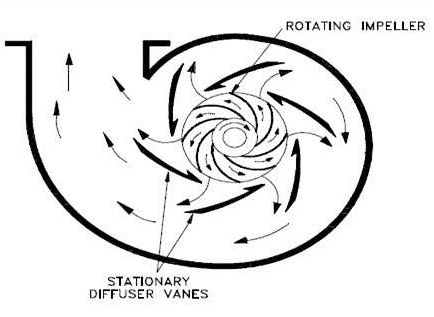

The casing is also known as the volute. The casing/volute in a horizontal centrifugal pump is the part that contains the fluid. This part acts as a pressure containment component that helps to direct the fluid in and out of the pump. The casing has a curved funnel shape that increases towards the discharge port. The casing is the part that receives the fluid from the impeller and it helps reduce the velocity of this fluid. In other words, the volute helps to convert kinetic energy into pressure energy thus it reduces velocity while it increases the pressure. Other horizontal centrifugal pumps have a diffuser. Diffusers are sets of stationary vanes surrounding the impeller. The diffuser(s) is used to direct flow by allowing more gradual expansion, hence increasing the pump’s efficiency.

Figure: Diffuser vanes on the impeller

Shaft

The shaft is the element on which the impeller is mounted. It is also connected to the motor so that it can transmit power from the electric motor and give it to the impeller.

Shaft sealing

Horizontal centrifugal pump manufacturers make the pump with a mechanical seal to help them prevent the fluid from leaking.

Bearings

Bearings are parts used by horizontal centrifugal pump manufacturers to constrain shaft relative motion as well as reduce friction between the stator and the shaft.

Delivery pipe

This is a pipe with one end connected to the pump outlet and the other end used for delivering the fluid being pumped.

Types of impellers used in horizontal centrifugal pumps

One of the main factors considered by horizontal centrifugal pump manufacturers is the impeller. When an impeller is properly designed it helps to optimize the flow by minimizing turbulence and thus maximizing efficiency. Horizontal centrifugal pump impellers are of three types which are:

Open impeller

The vanes on this type of impeller are free on both ends. These types of impellers are recommended for use in inexpensive, small-diameter pumps and those pumps meant for handling suspended solids. This is because these impellers are structurally weak.

Figure: Open impeller

Semi-open impeller

The vanes in this type of impeller are enclosed on the side and free on the other side. They have a shroud that is meant to enhance strength. These impellers have higher efficiencies relative to open impellers. These impellers are applicable in medium-diameter pumps for pumping fluids with small sizes of suspended solids.

Figure: Open impeller

Closed impeller

The closed impeller has the vanes positioned between two discs in a single casting. These impellers are used to manufacture pumps that have low net positive suction heads and high efficiencies. Closed impellers are most commonly used to manufacture pumps that handle clear liquids. These impellers are more expensive and complicated to design.

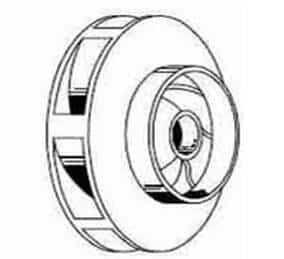

Figure: Closed impeller

Factors that determine the working of a centrifugal horizontal pump

Suction pressure

When the pressure at the suction is below the required level, cavitation may occur. Cavitation impacts pump performance severely and can cause permanent damage to the impeller.

Suction flow

For a centrifugal horizontal pump to operate according to its design, the pump will need to have the fluid flowing constantly at the suction port. When the suction flow reduces, flow at the discharge will reduce accordingly. When the suction does not have flow, this causes damage to the internal parts of the pump.

Fluid viscosity

A horizontal centrifugal pump is ideal for pumping low viscosity and clean fluid. However, a horizontal centrifugal pump can still be used to pump more viscous fluid but this will come at a cost of more power and it would likely be less efficient.

Fluid’s vapor pressure

Fluid flow at low vapor pressure could lead to cavitation. However, when the need arises to pump such fluid it is necessary to make sure that there is enough pressure all the time in the system.

Fluid density

The denser a fluid is, the more power it needs to move from one place to another.

Types of horizontal centrifugal pumps

Single-stage horizontal centrifugal pump

The single-stage horizontal centrifugal pump employs one impeller in its casing. The use of a single impeller makes these pumps easier to do repair and maintenance. A single-stage horizontal centrifugal pump is best suitable for use in fluids with low pressure and a large flow rate.

Two-stage horizontal centrifugal pump

A two-stage horizontal centrifugal pump employs two impellers that work together to pump fluid. This type of pump is best suitable for applications of the medium head.

Multi-stage horizontal centrifugal pump

A multi-stage horizontal centrifugal pump is a pump that employs more than two impellers. This type of pump is used where maximum efficiency is required and applications of the high head.

Applications of centrifugal horizontal pump

- A horizontal centrifugal pump is used to pump fluid at high temperatures.

- Horizontal centrifugal pumps are used in pumping fluids used in the heating ventilation and air conditioning.

- A horizontal centrifugal pump is used to supply domestic water.

- It is used to pump water for irrigation in farmland.

- A horizontal centrifugal pump is used to transport chemicals in factories.

- These pumps are used to pump gas and oil in the petroleum industry.

- Horizontal centrifugal pumps are used in high-pressure washing/cleaning facilities.

Advantages of centrifugal horizontal pumps

- Horizontal centrifugal pumps are easy to install and do maintenance because their internal parts such as the rotor can be accessed easily.

- Horizontal centrifugal pumps offer safe coupling with external parts such as electric motors, engines, or turbines.

- Horizontal centrifugal pumps are well suited for indoor applications because of the pump’s low headroom thus they can fit in cramped spaces.

- Horizontal centrifugal pumps are free from vibration, dynamically balanced, and are easier to operate.

- Horizontal centrifugal pumps are free from noise if well aligned according to the manufacturer’s instructions.

- Horizontal centrifugal pumps are fluid-tight, thus there is an entry of air during pressure transmission into the fluid.

- Horizontal centrifugal pumps have high efficiency and low intervals of failure.

Disadvantages of horizontal centrifugal pumps

- The horizontal centrifugal pump’s capacity to provide a net pressure suction head (NPSH) is limited.

- Space for installing horizontal centrifugal pumps is more due to the presence of a horizontal shaft.

- These pumps working pressure and temperature are lower relative to the vertical centrifugal pump.

Troubleshooting of centrifugal horizontal pumps

No or little discharge

- This could be due to insufficient fluid in the casing. In this case, the casing needs to be filled with fluid.

- The total head is too high for the pump. As such, the head or suction needs to be shortened.

- The suction lift is very long or too high. In such cases, the possible solutions are to shorten the suction length and lower the suction lift.

- The impeller is damaged and it needs to be repaired.

- “O” ring or casing gasket is leaking. It needs to be replaced.

- The wiring of the motor is incorrect. In this case, the wiring diagram needs to be checked again.

Suction loss

- There is air leakage in the suction line. This problem can be solved by repairing the suction line.

- A foot valve is clogged. It needs to be unclogged.

- The suction lift is very high. The suction lift needs to be lowered or installed foot valve and prime.

Leakage at the shaft

- This could be due to a worn-out mechanical seal. The solution is to just replace the seal.

- Foundation or mounting place is not strong enough. The solution is to reinforce it.

- The impeller is damaged and it needs to be repealed.

- There are foreign materials in the pump and this world needs to dismantle the pump for cleaning.

- Motor bearings are worn out and they need to be replaced.

The motor is overheating and shutting off

- There is a low voltage at the motor. The electrical connections need to be checked to make sure they are tight.

- The power supply voltage is not matching the motor voltage. The motor connection needs to be checked to see it is according to the wiring diagram on the motor and that it matches the supply voltage.

- The impeller is not running freely or it is rubbing against the casing. The pumps need to be dismantled and replace or unclog the impeller.

Pump not developing pressure or not delivering fluid

- This could be due to the pump not being primed. Fill the pump casing with fluid.

- There is leakage in the mechanical seal. The seal needs to be replaced.

- There is leakage in the suction line. The suction line needs to be replaced.

- There is leakage in the foot valve. The foot valve needs to be replaced.

The pump is not starting or running

- The pump wiring is incorrect. The wiring needs to be checked against the motor nameplate diagram.

- Foreign material is lodged in the impeller. This would need to dismantle the pump to remove that material.

- The motor has shorted. It needs to be replaced.

Summary

Horizontal centrifugal pumps are centrifugal pumps oriented in the horizontal plane. These pumps work by using rotating impellers that create vacuum pressure in the pump casing forcing fluid into the suction line. As the fluid passes the impeller it meets the casing that helps to reduce the fluid speed and at the same time increase the pressure energy on the fluid. The fluid moves via the delivery pipe and the piping system using pressure energy. Horizontal centrifugal pumps are of three types based on the number of impellers used. These are single-stage horizontal centrifugal pump, double-stage horizontal centrifugal pump, and multi-stage horizontal centrifugal pump. These pumps are used in different applications such as pumping water for domestic use, pumping water for farmland irrigation, pumping chemicals in industrial applications among others. Horizontal centrifugal pumps are advantageous in different aspects such as they need less headroom to install, they are easy to install and maintain, they offer safe coupling, and once installed according to manufacturer’s instructions they are free from noise.